Surely we all know that a car will have extremely important parts. And one of the parts I want to introduce to you today is the gearbox. The AT automatic transmission offers many benefits and versatility that any driver will appreciate. However, MT cars are not inferior! What is AT gearbox? What are their advantages and disadvantages compared to TM. Join me to learn more in the article below!

What is AT gearbox?

What does AT mean?

What is AT gearbox? Here, AT is the abbreviation for the English phrase “Automatic Transmission”, meaning automatic transmission. One of the types of gear reducers with the most complex structure and operating principles today. Furthermore, this is also a type of gearbox that integrates the most advanced technology and features to support the driver’s steering.

What is the meaning of AT?

This type of automatic transmission (AT) was developed and improved to help the driver not have to perform too many manual operations like other MT vehicles. Instead, these operations will be performed automatically. It helps a lot for those who are just starting to learn to drive.+

Advantages and disadvantages of AT gearbox

AT gearbox appeared on the market from 1940 until today, it increasingly asserts its superiority in the automobile industry and is well received by many drivers. Currently, if you pay attention, you can see that most car models sold in the Vietnamese market are equipped with automatic transmissions.

Vehicles using automatic transmission (AT) are considered a modern type of transmission. During operation, the use of manual controls can be limited. Thanks to that, it creates a feeling of comfort, flexibility and convenience when driving.

Advantage

- Easier to use: Due to the automatic nature of this type of transmission, the driver only needs to start, put the gear and press the accelerator to move the vehicle without having to use the clutch and shift gears like the current MT vehicle. onion. Thus, providing an easier and more comfortable experience, especially for weak riders.

- Useful when using the car in crowded urban areas: for manual transmission cars, the driver must be extremely focused so that the car does not stall at low speeds. Meanwhile, AT vehicles allow the driver to completely actively move without having to perform many operations. This is also a factor that helps AT vehicles save more fuel than MT vehicles

- Move more easily in mountainous areas: MT vehicles are difficult to manage on mountain roads, but AT vehicles solve this problem better by allowing the driver to use the automatic gearshift lever to change gears flexibly.

Defect

- Maintenance, repair and replacement costs are quite high: because the system structure of AT vehicles is quite complex, for example there are many parts: hydraulic pump, electronic controller,… this will cause waste. a lot of time and money. .

- More fuel consumption: Vehicles with automatic transmissions consume energy to operate the hydraulic pump. Meanwhile, manual transmission cars do not need a hydraulic pump, so they save more energy when running long distances.

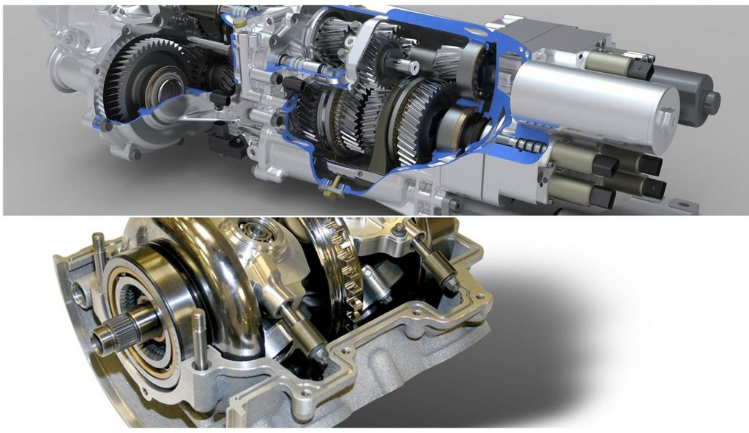

Structure of automatic transmission AT

The structure of the entire powertrain system of a car will include: engine, gearbox, differential and final drive. Manual transmission cars use a mechanical clutch. Automatic transmission cars use hydraulic clutches. Therefore, on cars using automatic transmissions, we can easily recognize that the car does not have a clutch pedal. The driver does not have to change gears. Everything is simple and automatic when you select D (driving) mode.

The automatic transmission works by adjusting the planetary gears to mesh with each other to create different gear ratios on the input and output.

The structure of a car automatic transmission includes:

- Planetary gear sets

- Hydraulic clutches

- Hydraulic torque converter

- Electronic controller

Planetary gear set

Planetary gear transmission plays the most important role in a car’s automatic transmission. Planetary gear structure includes:

- Sun gear (also known as small gear): is the largest sized gear, located in the center.

- Planetary gear: is a smaller sized planetary gear that meshes with and rotates around the sun gear.

- Outer belt: The outer belt covers the planetary and planetary gear assembly. This belt meshes with the planetary gear. In an automatic transmission, the outer surface of the outer belt is designed with many grooves to match the friction discs of the clutch. This helps the friction discs move with the outer belt.

- Planetary cage: the shaft of the planetary gear is connected to a planetary cage (guide rod) coaxial with the planet and the outer belt.

Any of the three elements of the sun wheel, planetary cage and outer ring can act as a torque conductor – input/master. At this time, one of the two remaining parts acts as a torque collector – output/secondary. The rest remains fixed. Changing the input or fixed section will give a different output speed ratio.

The gear ratio decreases when the input speed is lower than the output speed. The transmission ratio increases when the input ratio is greater than the output ratio. When the gear is reduced with reverse in and out movements, reverse gear is applied.

Deceleration: In this mode, the outer ring is active – the planet is fixed – the planet cage is passive. When the outer belt rotates clockwise, the planetary gear also rotates clockwise. This leads to a decrease in the speed of the planetary cage.

Acceleration: In this mode, the outer belt is passive – the planet is fixed – the planet cage is active. When the planetary gear rotates clockwise, the outer ring will accelerate to rotate as well.

Inversion: In this mode, the outer ring is passive – the planet is active – the planetary cage is fixed. When the sun gear rotates clockwise, because the planetary cage is fixed, the planet gear rotates counterclockwise. This causes the outer belt to also rotate counterclockwise.

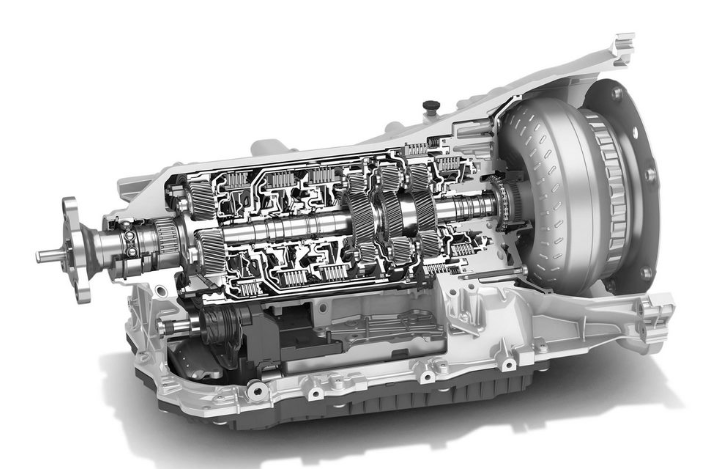

Hydraulic clutch

The hydraulic clutch includes:

- Friction discs

- Friction steel plates

- Spring

- Piston

The friction plate and friction steel plate are designed to overlap each other. The friction disc meshes with the outer belt of the planetary gear by grooves. When the outer belt moves, the clutch discs also move. The spring is responsible for separating the friction plates from each other when oil pressure is reduced or absent. When oil pressure increases, the spring moves to the right, the friction discs press against each other. At this time the planetary gear belt is retained.

Hydraulic torque converter

A hydraulic torque converter is a type of hydraulic coupling that transmits torque from the engine to the shaft and then to the gearbox. The hydraulic torque converter is located right between the engine and transmission.

The structure of the hydraulic torque converter includes:

- The pump gear is connected to the motor

- The stator is oriented to the medium

- The turbine connects to the gearbox

The working principle of a torque converter can be visualized by placing two fans facing each other. Fan 1 plays the role of turbine, fan 2 plays the role of turbine. Air in liquid form will move from fan 1 to fan blade 2, causing fan 2 to rotate and return to fan 1.

Vehicle stops: When the vehicle stops, the engine is still running, the engine still drives the impeller but is not stiff enough to drive the turbine. When the car starts rolling, the pump wheel rotates faster than the turbine’s rotation speed. At this point, amplification begins to take place due to the large difference between the speed of the pump impeller and that of the turbine.

The vehicle accelerates: when the vehicle accelerates, the pump impeller rotates faster, causing the impeller to also rotate faster. The gain will decrease as the turbine speed increases.

Coupling point: When the turbine speed increases to about 90% of the turbine speed (usually in the range of 60 km/h), the torque gain is zero. At this point, the torque converter actually acts as a cooling coupling between the engine and transmission.

In addition to the above main role, the hydraulic torque converter is also responsible for driving the car’s transmission oil pump. When the pump wheel rotates, the impeller also rotates to help absorb hydraulic oil and transfer it to the hydraulic system inside the gearbox.

Electronic controller

The car can shift gears automatically mainly thanks to the electronic controller. This controller receives input from sensors. Then process the information and supply power to the valves that open and close the oil lines to the clutches.

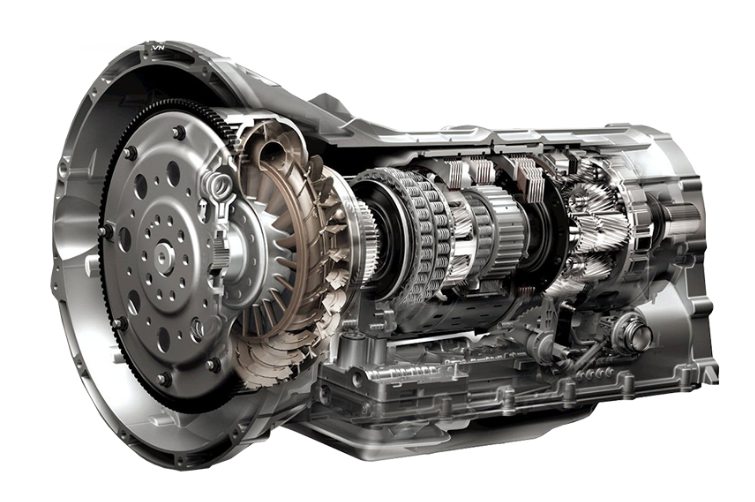

Operating principle of AT automatic transmission

Each number will have a corresponding clutch and planetary gear set, such as number 1 will have clutch 1 and planetary gear set 1, number 2 will have clutch 2 and planetary gear set. 2nd planet… the corresponding pairs of clutches and planetary gears are arranged along the drive shaft. In addition to the digital clutch, there is also a front clutch.

The operating principle of the automatic transmission is as follows: torque from the engine crankshaft is transmitted through the torque converter, and from the torque converter to the input shaft of the transmission. The electronic control unit, through the signal from the sensor, will open and close the oil path leading to the clutch. In order for torque to be transmitted to the output shaft of the gearbox, the two clutches must be closed.

- If the vehicle is moving forward: the forward clutch and gear clutch (1st or 2nd gear, etc.) corresponding to the vehicle speed will be engaged.

- If the vehicle is in neutral gear N: only 1 clutch 2 is closed. Front clutch does not close. This is the reason why torque cannot be transmitted to the output shaft of the gearbox.

- If the vehicle reverses: clutch 2 and clutch 5 close (with automatic transmission with 5 forward gears and 1 reverse gear).

1st gear: 1st gear is achieved by closing the coin clutch and 1st gear clutch. The forward clutch is used to transmit torque from the torque converter to the transmission input shaft. This is considered the “gateway” to the gearbox. Clutch 1 closes, torque is transmitted by planetary gear sets 1 and 2… then transmitted to the output shaft of the gearbox.

Number 2: The process of shifting to number 2 is similar. The front clutch is closed allowing torque to be transmitted from the torque converter shaft to the transmission. Clutch 2 closes to help drive planetary gears 2 and 3, then transmit to the output shaft of the gearbox.

Reverse: When in reverse, the 5th clutch closes allowing torque to be transferred from the torque converter shaft to the sun gear shaft. Clutch #2 closes, holding the outer belt of planetary gear set #2. Torque changes direction as it is transmitted from the sun gear shaft to planetary gear sets #2. Torque changes direction direction as it is transmitted to the tree. exit the gearbox.

Today’s automatic transmissions also have additional functions such as controlling engine speed as well as throttle position, monitoring the ABS braking system…

Compare AT gearbox and other types

Compare AT and MT gearboxes

If you feel confused and still wondering between AT and MT vehicles, please see the comparison table below. Based on this table, you can weigh the differences between the two models and make a decision that suits your needs!

| Factors | Automatic transmission vehicle (AT) | Manual transmission vehicle (MT) |

| Car purchase costs | Higher | Lower |

| Using | Easier to use | More difficult to use |

| Maintenance and repair costs | Higher | Medium |

| Acceleration ability | Slower acceleration | Accelerate faster |

| Safety level | Difficult to control because it’s easy to mistakenly press the gas pedal and the brake pedal | Safer because it is easier to control |

| Fuel saving ability | – Less fuel consumption when traveling in urban areas– Consumes more fuel when traveling on the road | – Less fuel consumption when traveling on the road– Consume more fuel when traveling in urban areas |

| Engine operation | The car automatically controls the engine | The driver controls the engine |

Should beginners choose MT or AT gearbox?

In fact, each type of car has its good and bad sides. Therefore, we will base on each case to determine which car is best. At the same time, it is necessary to base on the specific needs and purposes of use, based on some of the following criteria:

If you choose a manual transmission MT

- Save fuel for long trips.

- Save money when using a car

- Save maintenance, repair and replacement costs

- Create a professional, approachable feel

- Driving MT will improve your driving skills a lot

In case of automatic transmission AT

- If you often drive a car in urban areas or cities during rush hours, you should choose a car with an automatic transmission.

- Does not require too much experience

- Not too complicated to control the car

- Meets personal and family needs

- Suitable for women and the elderly

Each type of manual transmission (MT) and automatic transmission (AT) vehicle will have different advantages and disadvantages. Both give the driver the most experience. Therefore, you can rely on the information comparing MT and AT vehicles that I have analyzed above to make your choice. In addition, each customer can choose the type of vehicle according to personal preferences and usage needs as well as economic conditions they may encounter.

Compare CVT and AT gearboxes

A continuously variable transmission (or CVT) is an automatic transmission with infinite gear ratios. CVT has no gears, so this type of transmission shifts smoothly, helping to save fuel. In 1958, Daf – the Dutch produced this type of transmission for cars and until now CVT is the second most popular type of automatic transmission on the market.

Structure: Unlike AT gearboxes that operate based on gears, CVT gearboxes do not have gears. They operate using a system of interchangeable pulleys connected by a belt. Specifically, the CVT gearbox includes 3 main parts: a metal (or rubber) belt that transmits high force, a system of variable input pulleys fixed to the engine shaft, and a system of output pulleys. leads to the wheels.

Operating principle: CVT uses a system of 2 pulleys connected together by belts. To accelerate or decelerate the vehicle, the groove of each pulley will slide in/out to change the height of each end of the belt, the ratio of changing the rotation radius on the pulley will create operating levels similar to a car gearbox. AT gear car.

| Comparison criteria | CVT gearbox | AT gearbox |

| Energy saving | CVT transmission is more fuel efficient than AT transmission. Because the CVT is not limited to a fixed gear ratio but continuously operates at peak performance given the vehicle speed and road conditions. A car’s engine will rarely run at a higher RPM than normal. There is no wasted movement of the engine’s internal workings and will always be at the correct ratio. These factors help CVT achieve maximum fuel economy and consume less energy than AT transmission. And that’s why this gearbox is often equipped on economy cars, fuel-efficient cars, and hybrid cars. | AT transmission is less fuel efficient than CVT transmission. Because an AT automatic transmission depends on gears, it will usually be in a less optimal gear ratio. |

| Emission level | CVT transmission helps the car produce less emissions because it always runs at an ideal RPM. | AT transmissions produce more emissions than CVT transmissions because they do not always run at the ideal RPM. So if you are looking for a car with lower emissions, users can choose a CVT transmission. |

| Weight | CVT transmissions are lighter in weight than AT transmissions because they don’t have as many moving parts or hydraulic fluid. This can result in better fuel efficiency, make the car go faster and provide better drivability, especially in a compact car. | AT transmissions are heavier than CVT transmissions because they have more structural parts. |

| Provide user experience | CVT gearbox provides a smoother experience for the driver. Thanks to the continuously variable gear ratio range, a CVT vehicle will not experience jerky movements when shifting gears while accelerating. This gearbox helps increase comfort for the driver of a vehicle with difficult acceleration. That is the main reason why cars such as compacts, which are not famous for their speed, are often equipped with CVTs.However, CVT transmission users find the driving experience not as enjoyable as the AT transmission, preferring to feel the engine power and the way the car changes gears rather than driving the car too smoothly. | The AT transmission provides a more enjoyable, realistic driving experience than the CVT transmission. Because the AT gearbox has a better connection between the engine and driver. |

| Ability to shift gears according to terrain | CVT transmission does not support this feature. | Cars with AT transmissions provide the ability to shift gears up or down to suit the driver’s needs. For example, when driving up or down hills, the driver may want to adjust the gear ratio to ensure the RPM is not too high or too low. |

| Sound out | CVT transmission makes a louder sound than AT transmission when operating. When accelerating the engine, the sound of the belt moving will be much more noticeable than the shifting sound of the AT automatic transmission. Some riders may feel uncomfortable because of this. | The AT transmission provides a quieter driving experience because when operating, the transmission does not make loud engine noises even at high RPM levels. |

| Price | The low cost of manufacturing a CVT gearbox (because it only needs to use 2 pulleys and 1 moving belt) helps the product price to be better. | Vehicles with AT transmissions often have higher prices than products using equivalent CVT transmissions. |

| Repair costs | CVT gearboxes are more expensive to repair than AT gearboxes. Mechanically, a CVT transmission is less complex than a conventional AT transmission, but that doesn’t mean the CVT is easier to operate. CVT transmissions need to be very accurately calibrated, and if repair service is needed, users may have a more difficult time finding technicians skilled in repairing this transmission. That may cause users to need more time and more money. | Which gearbox is more durable, CVT or AT? AT transmission has higher durability and lower repair costs than CVT transmission. |

Which type of CVT or AT gearbox is better?

In fact, it is difficult to determine which type of CVT or AT gearbox is better because there is no best type of gearbox, whether the AT or CVT gearbox is superior depends on the user’s needs. Users must clearly understand the advantages and disadvantages of each type of gearbox to be able to make the right choice for themselves and their driving style.

Although AT automatic transmissions are by far the most popular, CVT transmissions have become increasingly popular over the years. Indeed, CVTs deliver better, smoother overall performance and are more fuel efficient – factors that are increasingly important to users. However, some people still like the feel of AT and its benefits.

With so many options available to users at car dealerships today, it can be difficult to determine which CVT and AT transmission is best and which is the best choice for someone looking to buy a car. Knowing the differences between the main parts, how they work, as well as the main advantages and disadvantages of AT and CVT gearboxes is necessary for users to make the most appropriate decision.

So, through the above article, I have introduced to readers in detail what AT is? What is AT gearbox? At the same time, provide a comparative analysis table for each type of gearbox in the most detailed way.